The World Robot Conference 2024, which kicked off in Beijing on Wednesday, claims to have showcased a record 27 different humanoid robots. Among the various robots of this exhibition, Optimus Tesla was also displayed behind a glass showcase; Tesla’s American robot entered a fierce competition with other Chinese robots.

According to the CNBC report, 27 humanoid robots were displayed at the World Robot Conference. Similar to China’s approach a few years ago, which directed various sources of industry and funds towards electric cars, now this Asian country is paying special attention to the development of humanoid robots.

According to the assessment of Chinese experts, the robot technology of Tesla and other American companies is probably one to two years ahead of China, but they believe that China has reached self-sufficiency in more than 95% of the humanoid robot supply chain. China wants to lead the race for humanoid robots that are expected to replace human workers on electric car production lines.

China’s record breaking at the Beijing World Robot Conference

According to an investor in China’s robotics industry, investment in the robotics sector has exceeded 100 billion yuan ($14.01 billion) in the past decade. According to the investors, the next milestone in the development of humanoid robots is expected to happen in the next one to two years, where robots can move and know how to prioritize certain tasks.

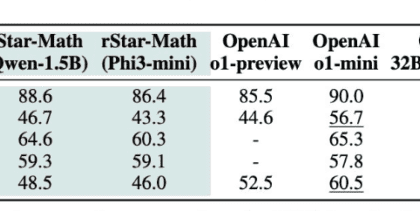

Multitasking is inherently more complex than repeating a single task like picking up a water bottle, which robots can already do. In the past few years, artificial intelligence, including the models of OpenAI and Alibaba, has significantly improved the development of robots in information processing to perform various tasks.

One of the remarkable points in this conference is the technologies of Chinese companies in the development of humanoid robots with cheaper and more creative parts; For example, the technology company Wisson uses 3D printed plastics and relies on pneumatic artificial muscles.

According to one of the company’s investors, this cheaper manufacturing method gives the company the opportunity to produce its flexible arms for about one-tenth the price of traditional robotic arms. These flexible arms can be used in humanoid robots.

RCO NEWS