In an age where fuel consumption optimization and driving experience have become the top priorities in the automotive industry, the CVT gearbox or “variable coefficient power transfer system” plays an important role as an innovative and efficient solution. This type of gearbox, which is found today in a wide range of domestic, Chinese and imported cars in the Iranian market, has been able to consolidate its position among a variety of automatic gearboxes by offering a unique combination of soft driving and optimal fuel consumption. In this article, with a deeper and more detailed look, we will examine the different angles of the CVT gearbox, from the history and how it works to its benefits, disadvantages and differences with traditional automatic gearboxes.

The emergence of the CVT Idea: From Da Vinci’s designs to the reality of modern cars

The original idea of the CVT gearbox dates back to the 15th century, when Italian artist and inventor Leonardo Da Vinci depicts the initial designs of a continuous variable power transmission system. However, the practical realization of this idea and its commercial use in cars required significant advances in materials science and mechanical engineering. Finally, in the twentieth century, with the development of resistant materials and precise manufacturing technologies, the CVT gearbox reached mass production and was used in passenger cars. Automakers at the time faced challenges such as designing small and efficient automatic gearboxes for light cars as well as increasing pressure to improve fuel consumption and reducing emissions, and CVT emerged as a promising solution.

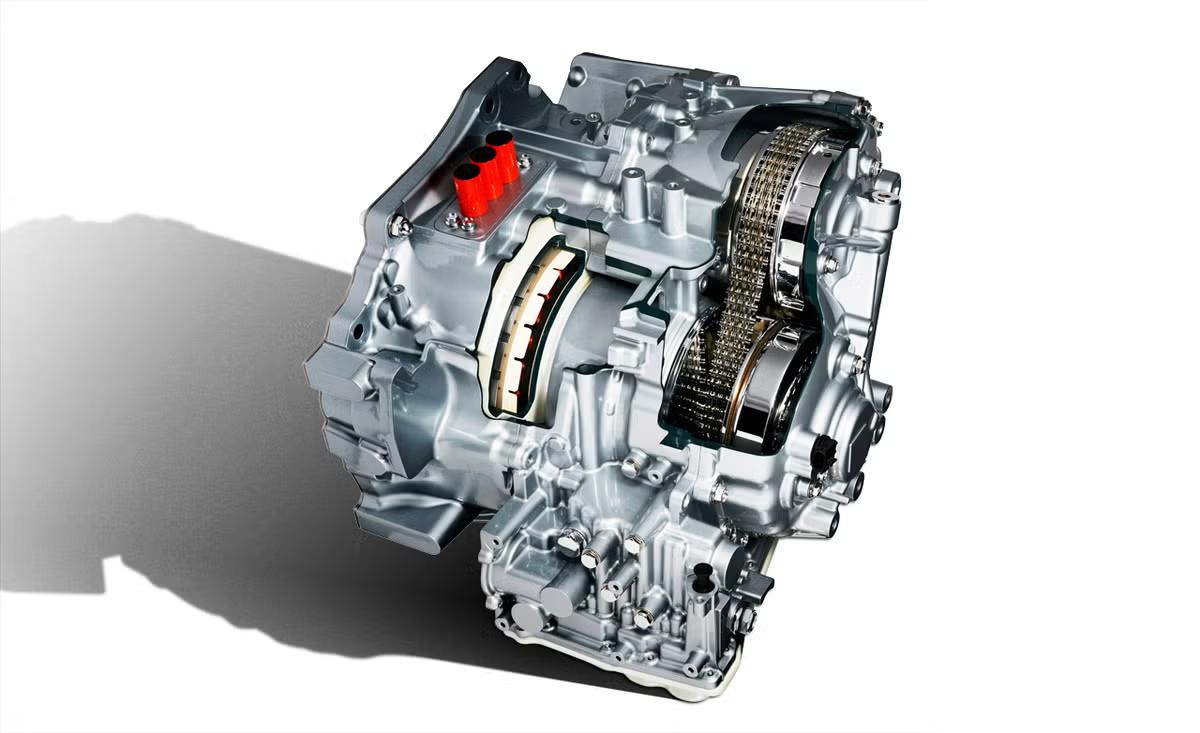

CVT Architecture and Function: Belt and pulleys performance for infinite gear change

The beating heart of the CVT gearbox is its unique structure in which there is no sophisticated set of planetary wheels found in traditional automatic gearboxes. Instead, the CVT uses two pairs of conical pulley (also called folk or foliage) and a power transmission belt (usually made of high -resistant steel or composite materials). One pair of these relics at the inlet of the gearbox is attached to the crankshaft, and the other in the output is responsible for the transfer of power to differential and wheels.

The fundamental difference in how CVT works compared to traditional gearboxes lies in how the gear ratio is changed. In conventional gearboxes, gear change is discrete and in specific speed ratios, which are determined by wheels of constant size. But in the CVT, the change of gear ratio is completely continuous and without any breaks. This process is done by changing the distance between the two halves of each pulley. As the half of a pulley approaches, its effective diameter increases and as they get away, effective diameter decreases. Since the strap is constant, the diameter change in a pair of pulley automatically causes the diameter in the other pair.

For example, when the car requires acceleration, the transmission computer orders to increase the gap between the half of the inlet pulley and, in contrast, reduce the distance between the output pulley. This makes the gear ratio changed to the “light” mode and the car with a higher engine speed gets more accelerated. In contrast, at fixed and high speeds, the TCU reduces the distance between the half of the inlet pulley and increases the gap between the half -pulley. This change drives the gear to “heavy” and reduces the engine speed at high speeds, which reduces fuel consumption and engine noise.

TCU is the responsibility of the TCU. This advanced control unit continuously receives and analyzes various information from sensors in different parts of the car (such as speed sensor, gas pedal sensor, engine speed sensor, etc.), and according to this information, selects the best gear ratio for current driving conditions. This process is done immediately without the driver’s intervention.

The benefits of the CVT gearbox:

The CVT gearbox, due to its specific structure and function, brings a set of significant benefits for drivers and cars:

- Unique optimization of fuel consumption: CVT’s ability to maintain the engine speed in the optimal range of torque is one of its biggest benefits. Compared to traditional automatic gearboxes that may be out of the optimum range when changing the engine, CVT always keeps the engine speed in the most efficient level. This can lead to a significant reduction in fuel consumption, especially in urban driving with heavy traffic.

- Excellent soft driving experience: Removing fixed gear and continuous change of gear ratio in CVT leads to a very soft driving experience without any shock or vibration caused by gear shifts. This feature, especially in long driving and in traffic, can help reduce driver fatigue and increase occupants’ comfort.

- Transfer of efficient power and proportionate to the need: The CVT is able to select a gear ratio at any moment that matches exactly the amount of force required by the vehicle. This makes the car optimized in a variety of driving conditions, from initial acceleration to uphill and high -speed driving.

- Losing weight and dimensions of gearbox: The simpler structure and the number of components in the CVT gearbox than traditional automatic gearboxes lead to weight loss and dimensions of the gearbox. This can help improve car handling as well as lose its overall weight, which in turn affects the fuel consumption and dynamic performance of the vehicle.

- Reduce engine depreciation: By maintaining the engine speed within the optimal range, the CVT gearbox can help reduce the depreciation of the engine and extend its lifespan.

- Easier to drive: No need for manual gearbox and smooth CVT’s smooth performance makes driving easier and more enjoyable for many people, especially in urban traffic.

Disadvantages of CVT Gearbox:

Despite all the benefits, the CVT gearbox also has the limitations and disadvantages:

- Restriction on very high torque tolerance: The CVT structure, especially its power transfer belt, is limited to the tolerance of very high torque. For this reason, this type of gearbox is usually not used in sports cars, offroads and heavy pickups that require a lot of torque.

- The relatively high sound of propulsion at high rounds (so -called “elasticity”): When accelerating or driving at high speeds, the engine speed may remain in a high range, creating a “elastic” or “howling” sound that is unpleasant for some drivers and occupants.

- Different feeling of acceleration (so -called “elasticity”): Due to the continuous change of gear ratio, the acceleration of CVT -powered cars may be different from traditional automatic gearbox cars. Some drivers may describe this feeling as a direct connection between the engine speed and the speed. This phenomenon is called “elastic effect” or “Rubber Band Effect”.

- Relative Maintenance Cost: CVT gearboxes, especially belts and pulleys, may be expensive, and repair may require special expertise and equipment. Also, the type of oil used in the CVT gearbox is different from traditional automatic gearbox oil and CVT oil should be used.

- Sensitivity to the type of driving: Fasting driving and sudden brakes can put more pressure on the belt and other CVT gearboxes and reduce its lifespan.

Comprehensive CVT Gearbox Comparison with AT: Priority Selection

Understanding the fundamental differences between the CVT gearbox and the AT (automatic gearbox with torque converter and planetary gearboxes) helps car buyers make more informed choice:

| Feature | CVT gearbox | AT automatic gearbox |

|---|---|---|

| Performance mechanism | Use two pairs of conical pulley and belt to continuous change of gear ratio | Using a set of planetary wheels and hydraulic clutches to change fixed gears |

| Number of gears | Infinitely (continuous change of ratio) | Limited number of gear (usually 1 to 2 gears or more) |

| Feeling gear shift | Very soft and smooth, without any interruption or impact | The tangible of gear shifts, especially in older models |

| Fuel productivity | Usually higher because of maintaining the engine speed in the optimum range | Usually lower than CVT |

| Production Cost | Usually lower | Usually higher |

| Maintenance cost | May have a higher cost in the event of a problem | Usually the cost of maintenance is more familiar and accessible |

| High torque tolerance | It has a limit | Has a higher tolerance to high torque |

| Acceleration experience | It may feel “elastic”, focusing on linear and continuous acceleration | The sense of gear shift and the gradual increase of engine speed may be more attractive to some |

| Weight and dimensions | Usually lighter and more compact | Usually heavier and larger |

CVT -equipped cars in the Iranian market: diversity in different classes

As mentioned, the CVT gearbox has been used in a wide range of cars available in the Iranian market. These cars include domestic models, Chinese carmakers and some imported cars. For example, the following cars are:

- Internal cars: Saipa (Sina Automatic, Automatic Quick, Automatic Hawk)

- Chinese cars: Cherry (Tigo 2, Tigo 2, Arizo 2, Arizo 2), MVM (X22, X33), Jack (J4, S3, S5) and many other Chinese brands on the market.

- Imported cars: Toyota (Row 2 in some models, Corolla in some markets), Nissan (X-Teril, Joke, Centra), Honda (Civic, CR-V), Subaru (most models) and so on (it should be noted that the exact list of models and their year of production may vary).

Correct Driving Guide with CVT Gearbox: Tips to Extend Life Life

Driving with a CVT gearbox is not much different from other automatic cars. However, observing some tips can help extend the gearbox life and improve driving experience:

- Avoiding sudden and very severe acceleration: As mentioned, too much pressure on the gas pedal can put a lot of pressure on the gearbox belt. Try to accelerate gradually and continuously.

- Avoid sudden and intense brakes: Sudden brakes can also put additional pressure on the power transmission system.

- Perform regular periodic services: Timely replacement of CVT gearbox oil with special oil and in accordance with the car manual is very important.

- Notice to warning signs: If you see any abnormal sound or vibration while driving, see a specialist repairer.

- Correct use of driving modes (if any): Some CVT -powered cars have different driving modes (such as sport or economical mode). Proper use of these modes can help improve car performance in different conditions.

Final Conclusion: CVT, a clever choice for modern driving?

The CVT gearbox has become an attractive option for many carmakers and buyers by offering a combination of soft driving, optimal fuel consumption and relatively simple structure. Although this type of gearbox may seem a little different for those who are used to the sense of traditional gear, it can provide a very good experience for everyday driving, especially in urban traffic. With the increasing advancement of technology, the future generations of CVT gearboxes are expected to play a more prominent role in the automotive industry and become a smarter choice for modern driving. Finally, choosing the right type of gearbox always depends on the needs, priorities and personal tastes of each person.

Sample Frequently Asked Questions

What is the main difference between the CVT gearbox and the ordinary automatic gearbox (AT)?

Answer: The main difference is how to change the gear ratio. The conventional automatic gearbox uses a set of fixed wheels, and gear shifts are performed at the specified and predetermined coefficients, which may be associated with a little interruption and impact. In contrast, the CVT gearbox uses two pairs of conical pulley and one belt, and the gear ratio changes continuously without any disruption. This leads to a softer driving and no gear shift in CVT -powered cars.

Is the CVT gearbox trusted and does it require special maintenance?

Answer: Modern CVT gearboxes have progressed greatly in terms of reliability and can have a long life if used properly and regular periodic services. However, maintaining a CVT gearbox requires some special attention. The most important thing is to use CVT gearbox oil and replace it at intervals recommended by the car manufacturer. It is also recommended that you avoid very fast -paced driving and sudden brakes that can put a lot of pressure on the gearbox belt.

Why may the sound of the engine when accelerating with a CVT gearbox can be different from ordinary automatic gearbox cars?

Answer: In cars equipped with CVT gearboxes, when accelerating, the engine speed may quickly reach a high range and remain in the same range so that the car will quickly reach the desired desired. This can create a sound similar to “elasticity” or “howling” that may be unfamiliar or even unpleasant for some people. In contrast, in conventional automatic gearboxes, gearboxes, the engine speed is increased and reduced. This difference in audio behavior is one of the functional features of the CVT gearbox.

Is the CVT gearbox suitable for sports driving?

Answer: In general, the CVT gearbox is designed to deliver soft and low -consumption driving and may not convey the desired feeling to the driver for very exciting and sporty driving. Due to the nature of the continuous change of gear ratio, the gearbox reaction to sudden changes in the gas pedal may not be the size of conventional automatic or rapid automatic gearboxes. However, some carmakers use different driving modes as well as simulating artificial gearboxes to make CVT more sporty in cars equipped with CVT, which can improve this feeling. Finally, the CVT’s appropriateness for the sport depends on the driver’s personal taste and the type of car.

RCO NEWS