Researchers have recently concluded that each 3D printer has a unique effect on its manufactured components, and these effects are highly accurate and tracked.

If you had a three -dimensional printing object, how much you were sure to accurately identify the printer he made? Maybe you had no chance of identifying the manufacturer without speculation. It is now clear that each printed piece has an unique “fingerprint” that allows the manufacturer to track it. This tracking specifies not only the printer model, but also exactly the device that made the piece, even if several devices are from one printer model.

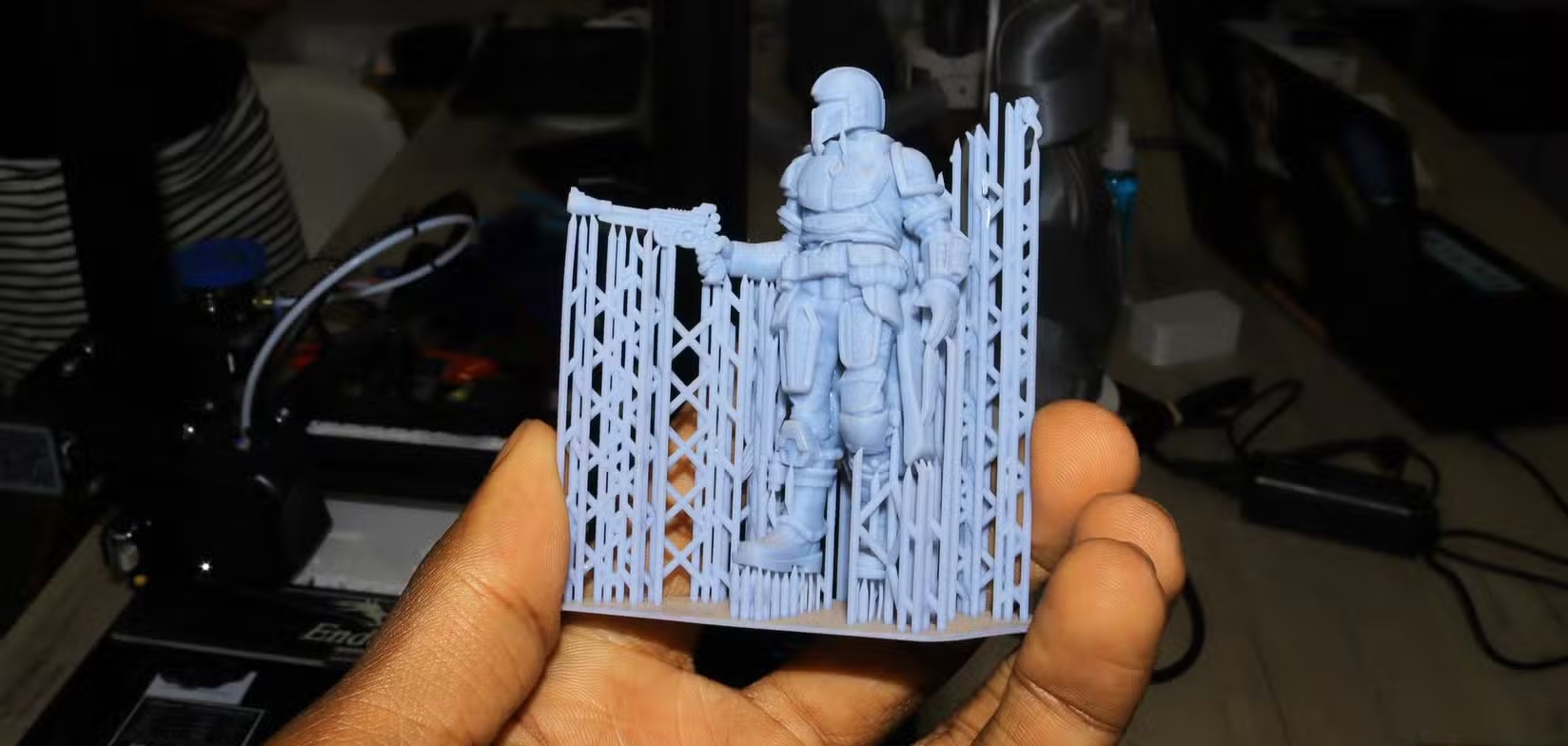

Researchers at the University of Illinois have discovered the “fingerprint” 3D printer that can identify a particular device. An image of a hand that holds a 3D printing file of a person with a gun shows the discovery. Researchers at the University of Illinois have found a reliable way to match 3D printing components with their manufacturer.

The research team works at the University of Illinois under the leadership of Bill King, a professor of mechanical and engineering science. After King’s discovery, they developed an artificial intelligence system that could analyze each piece and identify the manufacturer.

To teach the artificial intelligence model, the research team took photos of different pieces. These components were manufactured by 2 different 3D printing units, including 2 brands and 2 different manufacturing processes. The researchers then presented a picture of a square millimeter of a printed piece to artificial intelligence, and artificial intelligence was able to connect the piece to its manufacturer with 2 % accuracy.

“We are still amazed at this method,” King said. We can print a uniform design of the piece on the same device, and each device has a unique fingerprint that the artificial intelligence model can track to the manufacturer. It is possible to accurately determine the location and how to build something. “You don’t need to believe your supplier talk about something.”

King believes that the technology is more advanced, so that artificial intelligence will only be able to provide a detailed reading after only 2 scans of parts printed by a device. He believes that the study will make it easier for people to detect the site of error in larger product production processes. If the quality of a particular product is low, people can quickly track 3D printing to the device it made and facilitate reporting difficult items in the production chain.

RCO NEWS