Princeton University researchers have developed a cement paste that is 5.6 times stronger than cement, mortar and other conventional cement-based building materials.

According to RCO News Agency, The paste has a tubular structure inspired by the human cortical bone structure that forms the outer layer of the femur.

According to RCO News Agency, according to the researchers, the tube-like structure cement paste can significantly increase the resistance to crack propagation and improve the ability to change shape without sudden failure.

This cement paste also has the potential to replace cement-based plastic and fiber materials.

The need for harder construction materials

Brittle cement-based materials used to build buildings must have high strength and toughness. Strength is related to a structure’s ability to withstand load, and toughness indicates whether it can effectively resist cracks and damage.

A building built with weak strength materials can collapse suddenly and cause severe damage to property and human life.

Shashank Gupta, senior researcher and PhD candidate at Princeton, says: “One of the challenges of engineering brittle building materials is that they collapse suddenly and catastrophically.”

For this reason, it is very important to develop building materials that show high resistance to cracking. In the event of damage, such materials must be able to safely distribute the impact throughout the structure rather than causing sudden collapse.

The science behind crack resistant cement paste

Researchers were looking for materials that naturally have high strength and toughness.

They encountered human cortical bone, which resists fracture and gives the femur the strength to support the body’s load.

Cortical bone consists of oval tubular components known as osteons that are loosely embedded in an organic matrix. This unique structure prevents sudden failure and increases the overall resistance to crack propagation.

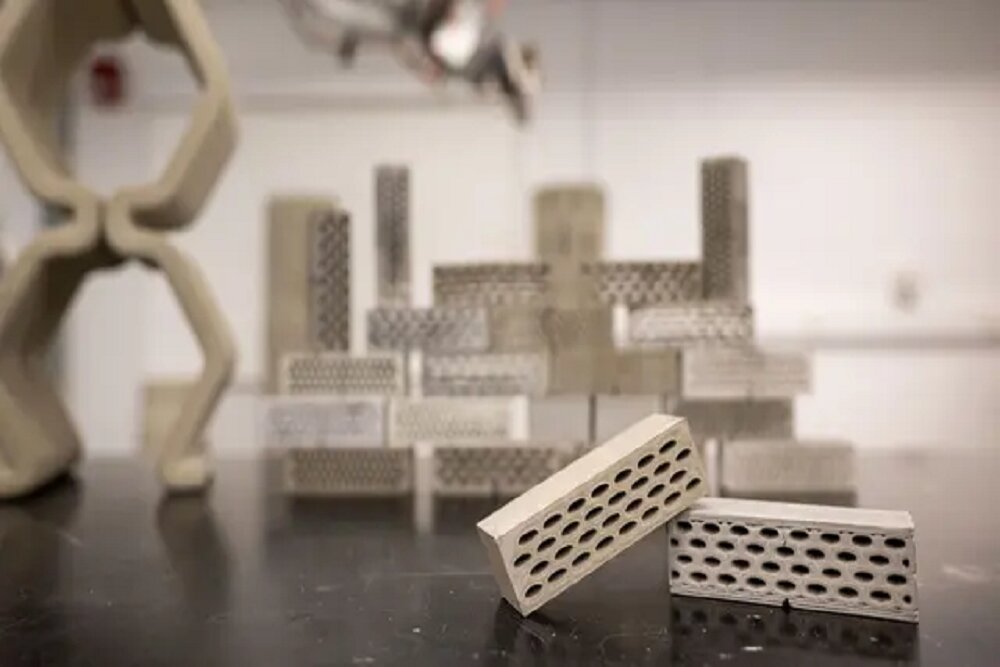

Inspired by the tubular structure of cortical bone, the researchers created a cement paste with cylindrical and elliptical tubes. These tubular structures have improved crack resistance properties.

For example, when a crack develops in a structure made with cement paste, it is trapped by the pipes and its spread to other parts is delayed. The crack limiting process absorbs energy.

This is the same energy that would otherwise cause the crack to grow faster. Energy dissipation gives the cement more time to resist damage and prevents the structure from suddenly collapsing. What makes this step-by-step mechanism unique is that each crack extension is controlled and sudden and catastrophic failure is avoided. Instead of breaking all at once, this material resists gradual damage.

In general, cement is reinforced with plastic, fibers and other materials to increase its strength. However, rather than adding anything extra to the cement, the current approach focuses on using tubular structures and geometry.

Reza Moini, a senior researcher and professor of civil and environmental engineering at Princeton, said: It is expected that when the hollow tubes are combined, the material becomes more resistant to cracking.

“We learned that by taking advantage of tube geometry, size, shape and orientation, we can enhance the crack-tube interaction to improve a feature,” he added.

This study was published in the journal Advanced Materials.

end of message

RCO NEWS